Flat Tappet Cam vs Roller Camshaft: What's the Difference?

By Sebastian Orellana

Updated Feb 17, 2024

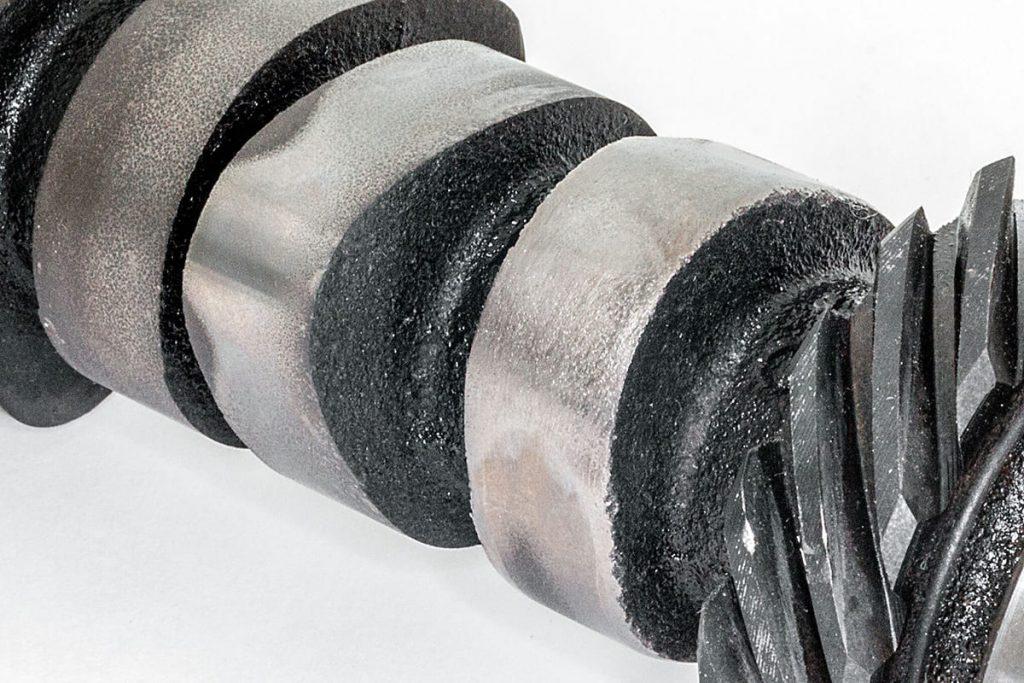

The engine is the heart of any vehicle, and the camshaft is its pulse. A camshaft is a rotating device that operates the valves of an engine. There are two main types of camshafts: flat tappets and roller tappet cams. Each has its advantages and disadvantages, so it’s essential to understand their differences before deciding.

Table of Contents

READ: The Best Custom G Body Chassis Manufacturer

Flat Tappet Cams

A flat tappet camshaft is the most basic type of camshaft. It has two flat, parallel surfaces that contact the rocker's arms and open and close the engine’s valves. The main benefit of a flat tappet camshaft is its simplicity. Its construction is relatively basic, making it a cost-effective option. Additionally, it’s relatively easy to install and maintain.

The downside of a flat tappet camshaft is that it’s not as efficient as a roller tappet camshaft. Due to the flat surfaces, the friction between the camshaft and the rocker's arms is higher, resulting in increased wear and tear. Additionally, the lack of precision can result in lower levels of performance.

Roller Tappet Cams

A roller tappet camshaft is a more advanced type of camshaft. It has cylindrical roller bearings that contact the rocker's arms and open and close the engine’s valves. The main benefit of a roller tappet camshaft is its efficiency. The roller bearings reduce the friction between the camshaft and the rocker's arms, increasing performance. Additionally, the higher levels of precision result in smoother operation and better fuel economy.

The downside of a roller tappets is that it’s more expensive than a flat tappet camshaft. Additionally, due to the complexity of its construction, it’s more challenging to install and maintain.

Comparison

There are several key factors to consider when comparing flat tappet and roller tappet camshafts. First, the cost is a significant factor. Flat tappet camshafts are much cheaper than roller tappet camshafts, making them more cost-effective.

Second, performance is an important consideration. Roller tappet camshafts are much more efficient than flat tappet camshafts, resulting in higher performance levels. Additionally, the precision of the roller bearings results in smoother operation and better fuel economy.

Finally, installation and maintenance are important factors to consider. Flat tappet camshafts are much easier to install and maintain, while roller tappet camshafts are more complex and require more expertise.

Applications

The type of camshaft used in an engine will depend on its intended application. Flat tappet camshafts are best suited for basic, low-performance applications. They are often used in smaller engines, such as those found in motorcycles and lawnmowers.

Roller tappet camshafts are best suited for high-performance applications. They are often used in larger engines, such as cars and trucks. Additionally, they are often used in racing applications, where every bit of performance is critical.

READ: Electric Truck Conversion Kit

Durability

The durability of a camshaft will depend on the type of camshaft used. Flat tappet camshafts are not as durable as roller tappet camshafts. The flat tappet camshaft's surfaces can wear out quickly, decreasing performance and increasing maintenance costs.

In contrast, roller tappet camshafts are much more durable. The roller bearings reduce the friction between the camshaft and the rocker's arms, increasing durability. Additionally, the higher levels of precision result in smoother operation and reduced wear and tear.

Longevity

The longevity of a camshaft will depend on the type of camshaft used and how it is maintained. Flat tappet camshafts are not as durable as roller tappet camshafts and may need to be replaced more frequently. Additionally, they require more frequent maintenance to ensure optimal performance.

Roller tappet camshafts are much more durable and require less maintenance. However, following the manufacturer’s maintenance schedule is still essential to ensure optimal performance and longevity.

Benefits

The benefits of flat and roller tappet camshafts will depend on the intended application. Flat tappet camshafts are best suited for basic, low-performance applications. They are relatively inexpensive and easy to install and maintain.

Roller tappet camshafts are best suited for high-performance applications. They are much more efficient than flat tappet camshafts, resulting in higher performance. Additionally, they require less maintenance and are more durable.

READ: How To Build Your EV Into A High-Performance Electric Car?

The Differences Between Flat Tappet and Roller Tappet Cams - Conclusion

Flat tappets and roller tappet camshafts are two types used in engines. Each has advantages and disadvantages, so it’s essential to understand the differences before deciding. Flat tappet camshafts are best suited for basic, low-performance applications, while roller tappet camshafts are best suited for high-performance applications. Each type's cost, performance, installation, maintenance, durability, and longevity should be considered when deciding.