There is a lot of debate surrounding the question of are 706 heads better than 243 heads. If you are looking to build an LS engine for either the road or the track, you are going to be looking for the cylinder heads that give you the flow and compression goals you need to meet for the performance you want to experience

Table of Contents

While both sets of GM LS cylinder heads will have their own benefits and drawbacks, they are both incredibly powerful heads to put on your GM power plant. We’re going to do a deep dive into what makes each one unique, and how they may be best applied in your build. The answer of whether 706 heads are better than 243 heads may depend largely on how you plan to use them and what engine you are putting them on.

What Are 706 Heads?

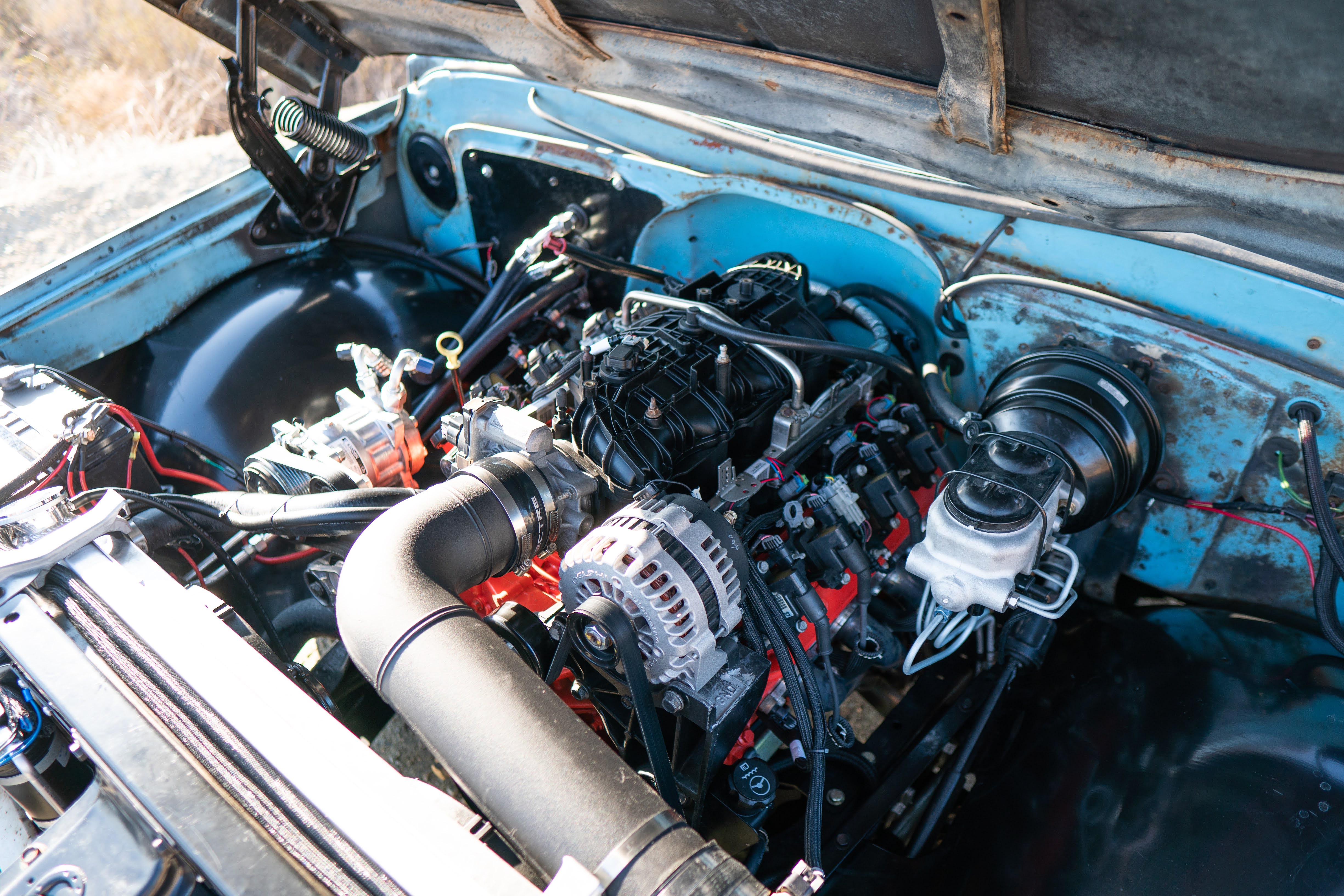

Stock form 706 heads are some of the absolute cheapest but most effective GM Vortec cylinder heads that you can put in your LS engines. They can be used with engines from 4.8L and up with dish pistons, with some even being used on unconventional or 6.0L LS. While many enthusiasts tend to overlook the 706 heads and their exhaust flow they have been shown to deliver excellent performance for boosted applications time and time again.

Casting numbers 706 heads are cathedral port heads, and due to this, their lower volume combustion chambers don’t tend to affect overall compression rates.

They are ultra-common heads to see on GM trucks with 4.8L and 5.3L engines, so they can be found in just about any scrapyard you have nearby. This also means that they are usually cheap to collect or replace.

706 heads tend to be more popular than 243 heads with those who run naturally aspirated engines. While they don’t have the same size combustion chamber they also don’t have the tendency to lower the compression ratio and reduce horsepower.

When looking to replace your heads, they offer a high degree of consistency since they are manufactured with a semi-permanent mold process instead of being cast.

What Are 243 Heads?

Also known as 799 heads, 243 heads are the best performing aluminum cylinder heads that were standard on 3rd generation GM LS6 & LS2 engines that were produced starting in 2004 & 2005, though they are most well-known for being the cylinder heads for the C5 Corvettes.

They have slightly larger combustion chambers, smaller valves with higher compression than the 706 heads at 64.45cc, they have the same ports style but they also have a larger intake port volume by 10cc.

They are used for such a wide range of V8 trucks, SUVs, and even van use that they are a very common performance upgrade for some LS builds, so they are plentiful and should not cost an arm and a leg to replace or stock up on.

These are great heads to consider if you want to raise the compression rate of your engine over earlier iterations of the LS1 motors.

243 heads have cathedral intake ports and D-shaped exhaust ports. 243 heads have a flow profile that makes them more adept at boosting torque on LS6 builds than LS1 since the exhaust has a better flow shape.

The 243 heads are most popular with people looking for a budget cast head to have ported.

How To Check 706 Heads

Do you know how to check 706 heads? In order to check 706 heads, first, take a look at the head's casting number. The casting numbers are on the top of each valve cover as well as the front and rear of each cylinder head. Once you have found your engine's casting number

What Is A Valve Job

What is a valve job? It's a procedure to replace the valves in an engine. A valve job can be done on either an inline or pushrod-style engine and many have a different valve size, but it's more commonly done on V8s and other larger engines.

Valve jobs are typically performed when the vehicle owner notices that their car is running roughly or is starting to lose compression. This could mean there are problems with one or more of the valves that need to be repaired.

The first step of a valve job is removing the old valves from the cylinder head, which may require some grinding and heavy-duty tools like a drill press and die grinder for smaller parts. Once all of them have been removed, new ones must go back into place as perfectly as possible.

Compression Ratio

A car's compression ratio is the measurement of how much air is compressed for every kilo of fuel that is burned. This measurement affects the performance, power, and efficiency of a car.

The more air can be pushed into the engine per kilogram of fuel consumed, the more efficient it will be. However, if too much air enters at once, so many particles are created that there isn't enough room to burn them all off before they escape out again through exhaust valves or spark plugs which causes backfiring and poor engine performance.

Achieving an ideal compression ratio involves finding a balance between these two extremes by determining what your engine needs in order to run smoothly without damaging it with excess pressure from gas entering when there isn't enough space inside

Combustion Chamber

The combustion chamber is the part of an engine where fuel and air are mixed together to create a chemical reaction, which creates the power to drive your vehicle.

The size of the combustion chamber determines how much power it can makeand modifying this could potentially make a huge improvement when it comes to power production.

The design of this piece affects how well your engine runs (poorly if not designed correctly). A poorly designed combustion chamber may cause poor fuel efficiency or even damage the car's other components.

It's important that you take time to research what type of design is best for your car's needs before installing one. If you're unsure, consult with someone who knows more about these engines than you do!

Why You May Not Be Able To Convert Flow Rates Directly Into Power

The 243 heads have the most flow, moving more than 20 cubic feet of air per minute more than the 706 heads. Even with this, bench testing indicates that the power they generate just isn’t up to par with their more restrictive counterparts.

While this may only be a few horsepower on the dyno, it can mean big changes for your engine at the track or on the road.

Test after test has shown the 706 heads to have a more powerful output over the majority of the RPM curve when compared to stock 243 heads.

This would likely change with the addition of boost or other forced aspiration, where the 706 heads would end up falling behind when the flow limit is reached.

How To Determine If 706 Heads Or 243 Heads Are Better For You

When you ask the question of whether 706 heads are better than 243 heads, you always need to think in the context of your project and your budget. If you have a bigger naturally aspirated engine, such as a 5.3L, and are going for a reliable and easy budget build on just about any common LS engine then you are probably going to be better off with the 706 heads.

They can get even better with porting and other machining efforts and adjustments, but that will often involve significant expense that is usually precluded by going with cheap and plentiful heads that are really good to start with.

On the other hand, if you are planning on the additional expense of machining the heads in order to get a more robust power curve, then you may want to consider getting the 243 heads. They are only marginally worse than the 706 heads, but with expensive porting, they can far surpass what the 706s are capable of. This would be a great idea for someone putting together a powerful foundation that can be improved upon at a later time for an absolutely insane horsepower increase.

What Did 706 Heads Come On

This is a difficult question to answer without first considering and understanding your engine build or project goals.

If you are not keen on the idea of spending more time and significantly more expense getting heads machined for your rig, then you are going to do just fine with the 706 heads. They give the best performance in their stock state than most other heads you can put on your LS.

If you are planning on modifying your heads later, however, the gains you’ll get on the 243 heads will far outstrip the gains you’d get by having your 706 heads machined with much more radical porting